STOP FLUSHING CAPITAL

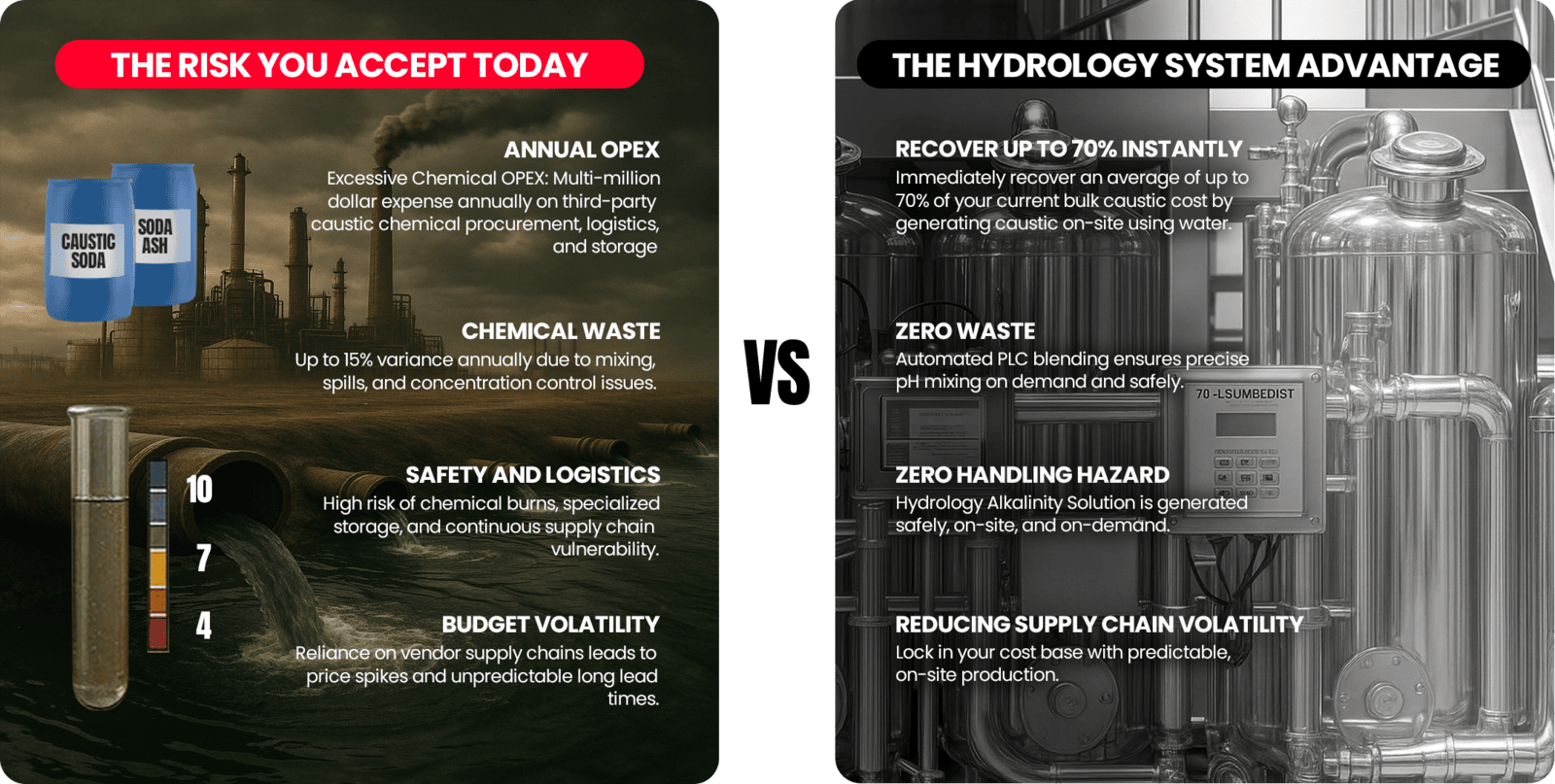

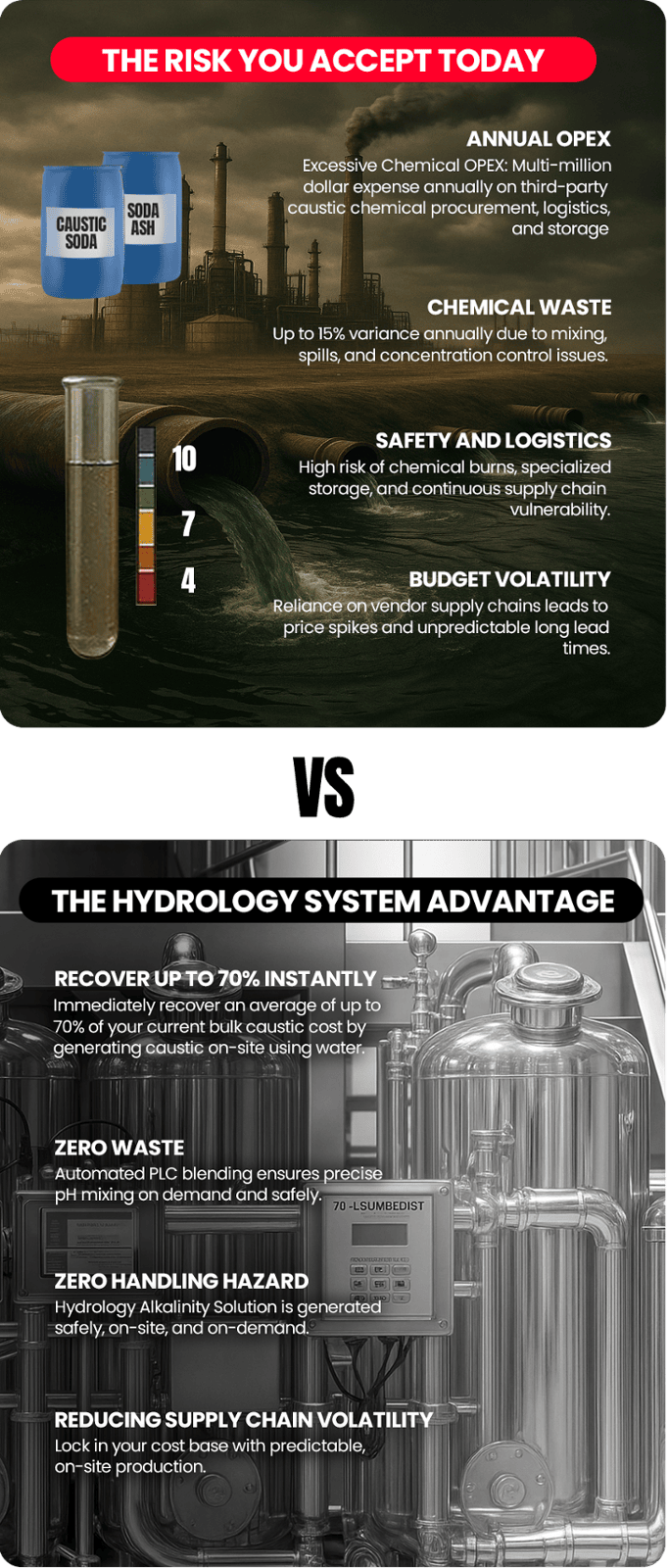

The True Burden of Bulk Caustic

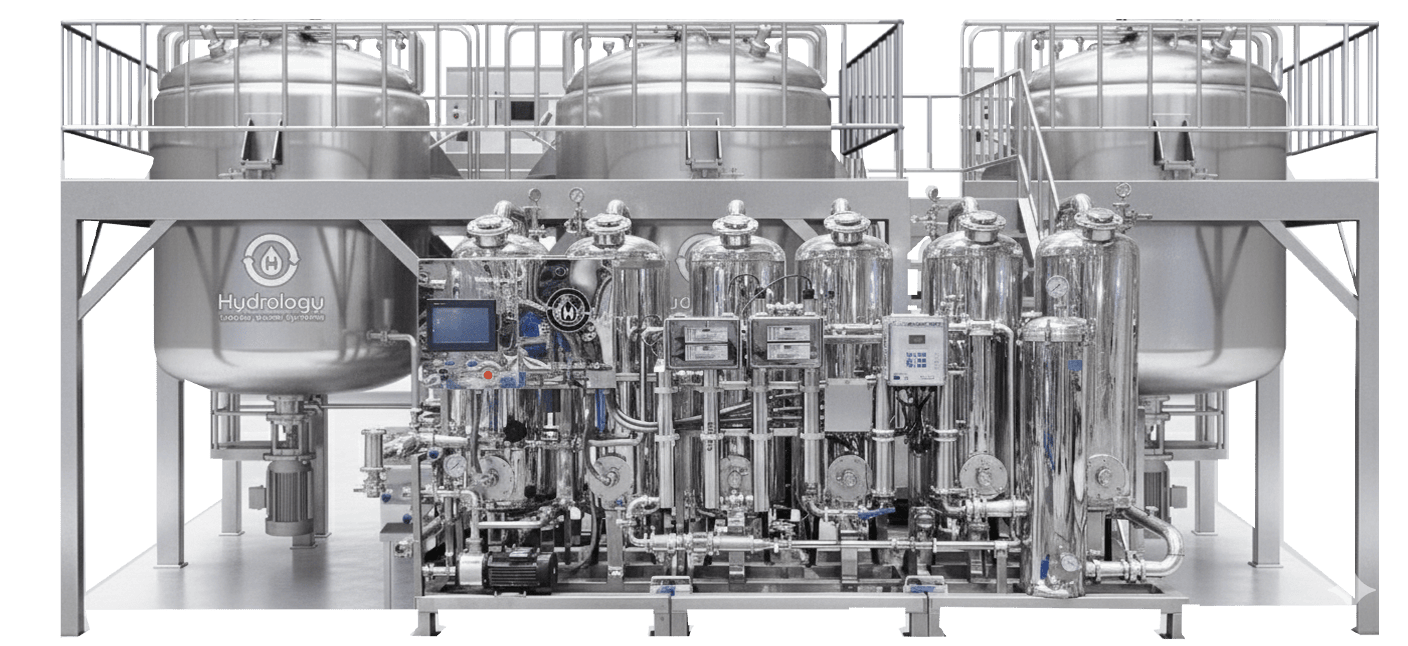

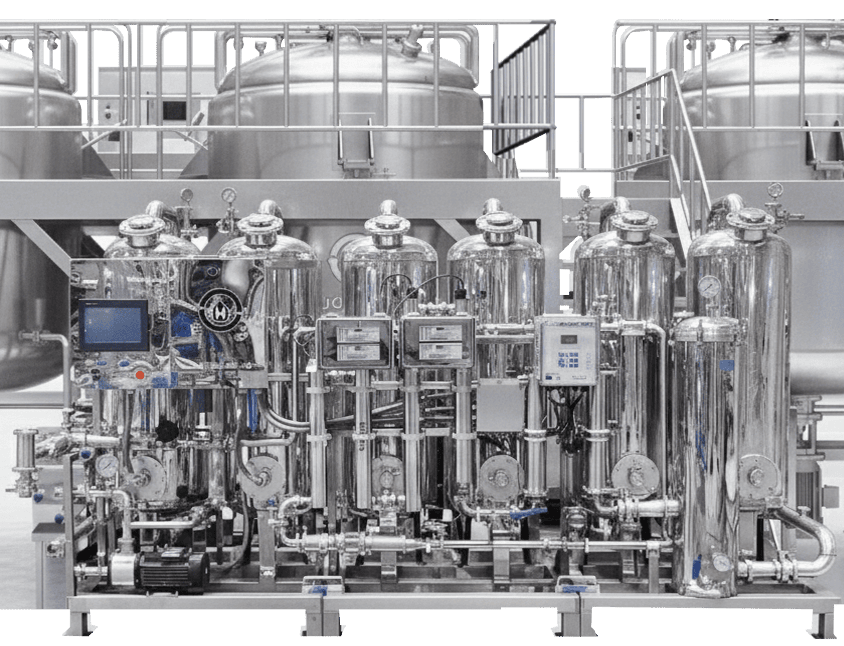

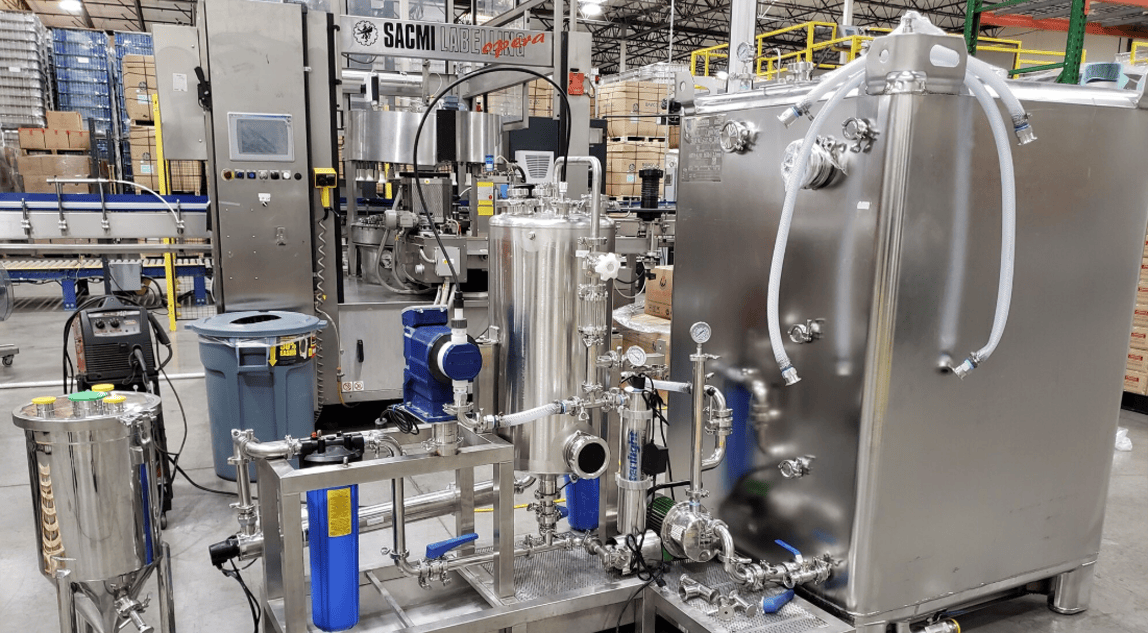

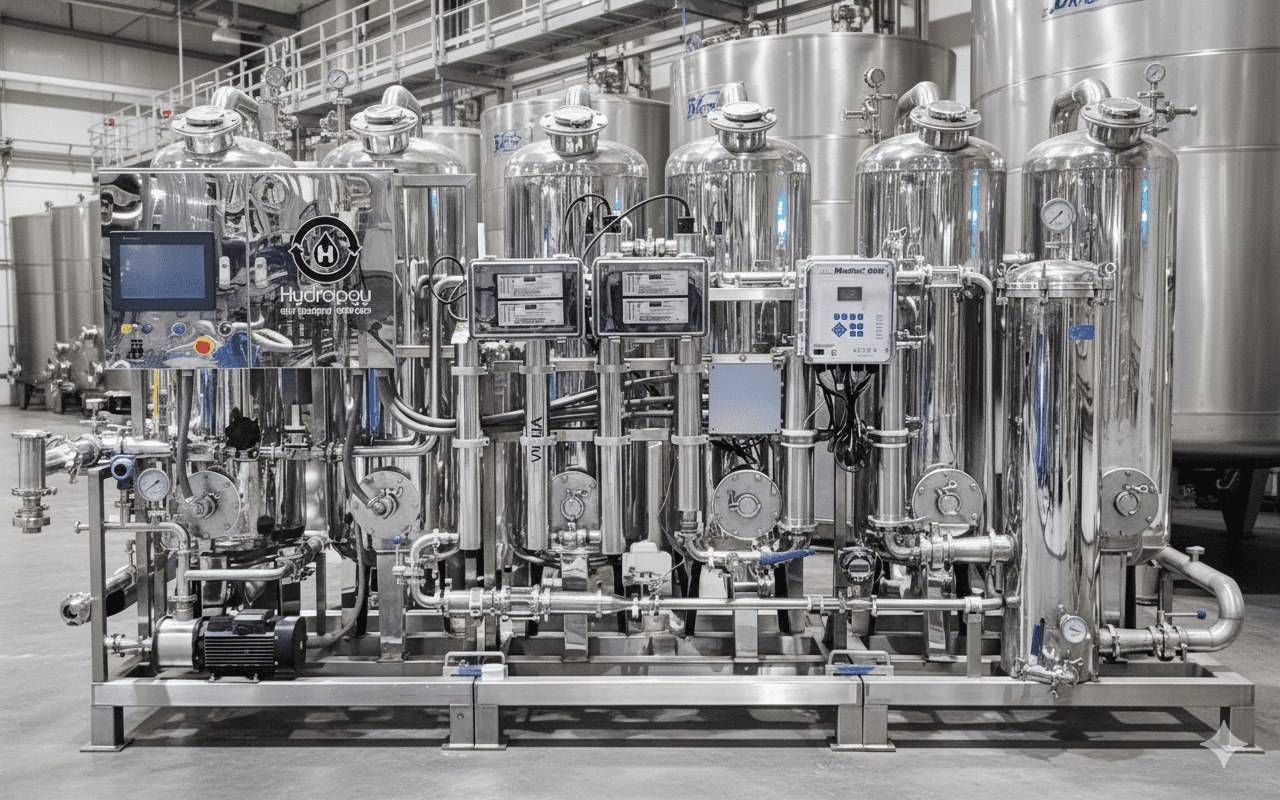

How It Works

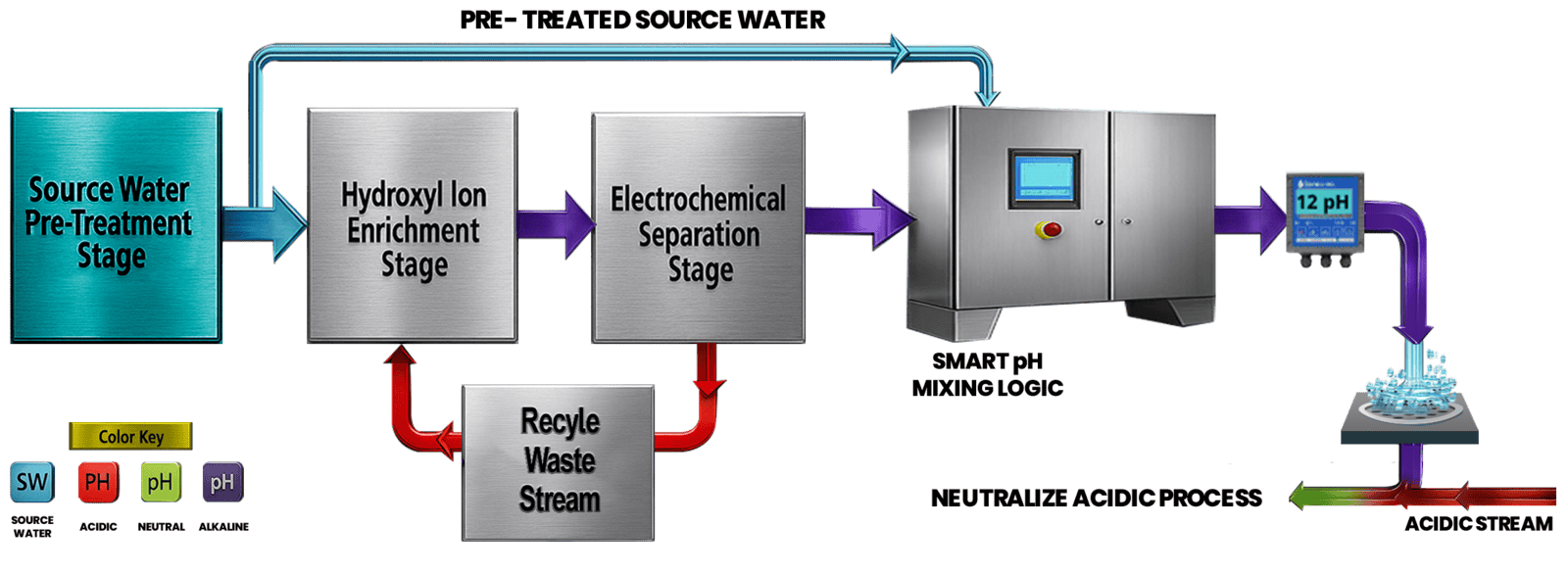

Simple Proccess Illustration

The Hydrology Process Platform transforms readily available site water into a high-purity neutralizing agent via our proprietary Hydroxide Catalyst Reactor (HCR) and Electrochemical Hydroxide Generator (EHG) Module. This closed-loop system provides precise, adjustable pH control (7-12) on demand, eliminating the need for hazardous bulk caustic chemicals.

T

Calculate Your Caustic Savings ROI

Determine your potential net annual savings by switching from bulk NaOH to the HAS Platform.

Volume unit is fixed to Gallons/Year.

This should include chemical cost, shipping, and handling.

Used for technical context.

Crucial for system sizing.

Estimated Annual Savings Forecast

Current Annual Spend (Baseline)

Estimated HAS Annual OPEX

Net Annual Savings (Calculated)

This calculation provides an estimate of your potential total OPEX reduction.

The Hydrology Alkalinization System (HAS)—including annual service and consumables—typically operates at about 30% of your current caustic spend. Depending on your final system design and volume requirements, your actual net savings may range from 50% to 70%.